USK Consulting Africa

Preparing your premium proposal...

Preparing your premium proposal...

Unlocking the potential of seven historical coal stockpiles through advanced assessment methodology and 3D/4D modeling for optimal synfuels production.

USK Consulting Africa presents a comprehensive solution to assess and unlock the value of SASOL's historical coal stockpiles through advanced sampling, analysis, and predictive modeling.

Systematic evaluation of seven stockpiles using ISO-compliant sampling methodology for gasification suitability.

Advanced predictive models providing actionable insights for optimal resource utilization and operational efficiency.

95% confidence intervals with rigorous QA/QC protocols ensuring defensible and actionable results.

Comprehensive analysis of seven strategic stockpiles totaling 2.4 million tons with advanced visualization and interactive controls.

Initial assessment and mapping

Week 1-2Side 1 & Side 4 assessment

Week 3-6Side 6 & Side 4 assessment

Week 7-12Remaining stockpiles

Week 13-16| Stockpile | Volume (tons) | Priority | Progress | Status |

|---|---|---|---|---|

| Side 1 | 757,944 | High | 32% | Active |

| Side 6 | 937,825 | Medium | 40% | Active |

| Side 4 | 313,217 | Medium | 14% | Pending |

| Side 4 | 59,508 | High | 4% | Pending |

| Side 2 | 85,428 | Medium | 4% | Pending |

| Side 3 | 112,200 | Low | 6% | Pending |

| Side 5 | 88,704 | Low | 4% | Pending |

Real-time satellite view of stockpile locations

26°34'28.79"S 29°9'4.83"E

26°34'33.40"S 29°10'10.30"E

Advanced interactive dashboard with real-time sampling visualization, methodology breakdown, and quality control monitoring for 95% confidence intervals.

Maximum 50,000 tons per lot ensures manageable sample volumes and statistical validity

8 drill points per lot, distributed in systematic grid with random start point (ASTM D6913)

Three discrete increments (top/middle/base) to capture vertical segregation effects

≥50 kg per increment exceeds ISO 13909 requirements for 125mm top size

Rubber Tracked Hydraulic Powered Drill equipped with Hollow-stem auger with continuous split-spoon sampling (152mm diameter)

Exceeds maximum particle size (125mm), eliminating bias from particle exclusion

10% duplicate (randomly selected) to quantify measurement precision

5% of lots undergo surface-vs-core comparisons to detect sampling bias

Post-sampling spatial variability assessment to optimize future programs

| Parameter | Confidence Interval (±) | Test Method | Standard |

|---|---|---|---|

| Ash Content % | ±1.8% (absolute) | ISO 1171 / ASTM D3174 | International |

| Sinks Content % | ±2.2% (absolute) | ISO 1953 (1.6 SG cut) | International |

| Fines Content % | ±3.0% (absolute) | ISO 1953 (-0.5mm) | International |

| Full PSD Grading | ±5% per size fraction | ISO 1953 (wet sieving) | International |

Mechanical Sampling from Stockpiles

SA Coal Characterization Norms

Sample Collection/Preparation

Quality Standards

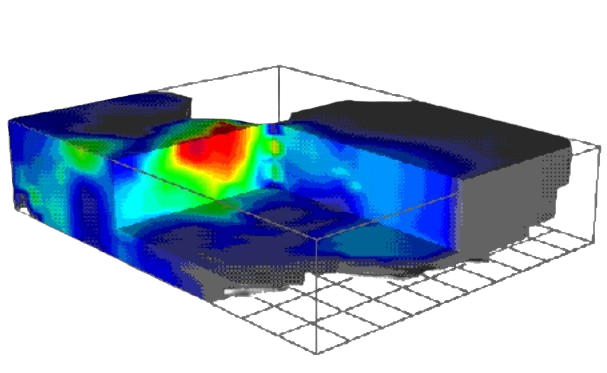

Utilizing Earth Volumetric Studio (EVS) to generate dynamic 3D models and time-based (4D) insights into coal stockpiles.

Advanced 3D visualization of stockpile sampling points and drill patterns

Validating precision and minimizing systematic errors through rigorous controls and international standards compliance.

10% duplicate (randomly selected) to quantify measurement precision and ensure data reliability

5% of lots undergo surface-vs-core comparisons to detect and eliminate sampling bias

Post-sampling spatial variability assessment to optimize future sampling programs

Phased approach optimizing resource allocation and risk management across 16 weeks of comprehensive assessment.

Comprehensive project cost breakdown with prioritized implementation and transparent cost structure.

Contact USK Consulting Africa to begin implementation of your comprehensive coal stockpile assessment solution.

Managing Director

Premium Mining Consultation

Industry Standard Compliance

Data-Driven Solutions